Shaw Stainless Fabrication Division is a premier stainless steel fabricator specializing in stainless steel bollards, DAF tanks, stainless steel pipe fabrication, and other custom stainless steel fabrication. From large-diameter stainless steel pipe, pipe spools, and complete stainless steel pipe systems to stainless platforms, railings, and stairs, we will customize a solution for your application. We are your stainless steel fabrication experts.

Shaw Stainless is equipped to create custom stainless steel fabrication pieces that conform to your specifications. Our facilities house state-of-the-art equipment, from welders, lathes, saws, and presses to square and round polishers, press brakes, and mills. Our stainless steel fabrication services include polishing, electropolishing & passivation, laser cutting, waterjet cutting, pipe threading, metal forming, roll grooving, and many other custom stainless steel services. From a single custom piece to a full line of stainless steel fabrication, our team of experts is ready to facilitate your order.

Fabricated Products

Our fabricated stainless steel products include pipe fabrication, railings, platforms, stairs, bollards, wastewater treatment systems, and manifolds—engineered for strength, precision, and long-term performance.

Pipe Fabrication

Custom stainless steel pipe fabrication, spools, and assemblies built to exact specifications.

Railings, Platforms and Stairs

Fabricated stainless steel railings, platforms, and stairs engineered for safety and durability.

Custom Fabrication

Tailored stainless steel fabrication services for unique parts, prototypes, and large projects.

Bollards

High-quality stainless steel bollards for traffic control, perimeter security, and safety needs.

Wastewater Treatment Systems

Stainless steel wastewater treatment systems including DAF tanks and custom solutions.

Stainless Steel Manifolds

Precision-engineered stainless steel manifolds, T-drill manifolds, and air manifolds for piping systems.

Fabrication Services

Our stainless steel fabrication services include advanced custom machining, laser cutting, metal forming, pipe threading and polishing, precision laser welding, and much more—providing the advanced fabrication capabilities you need for projects of any scale.

Fabrication Operations

Shaw Stainless' in-house fabrication operation is fully equipped to provide bollards and architectural products in a wide variety of austenitic stainless steel materials. We pride ourselves on the close integration between our engineering and fabrication staffs to minimize errors and to provide immediate problem resolution should any fabrication issue arise. Shaw Stainless specializes in the design and fabrication of stainless steel products for governmental, industrial and commercial interests.

Fabrication Capabilities

Shaw Stainless’ custom fabrication operations range in size from small one-off applications in scale to large industrial, commercial or governmental projects. Our metal fabrication operations have the equipment and capability to cut, shear, bend, roll, and fabricate large sheets of metals. We also have computer numerical controlled (CNC), laser cutter to accurately cut complex components. Our precision CNC Plate Rolls or Press Brake are utilized in the forming process of bollards to each customer’s unique design requirement and tolerances.

Fabrication Services

We offer fabrication services enhancing our quality stainless steel products. Our stainless pipe, square tube, rectangular tube, bar, angle, and most other long products can be polished in-house. We have electropolishing & passivation services, custom threading, and roll grooving to schedule 40 pipe and above, are some of the value-added services we offer here at Shaw Stainless. Visit our stainless steel services page if you are interested in learning more about our value-added stainless steel services.

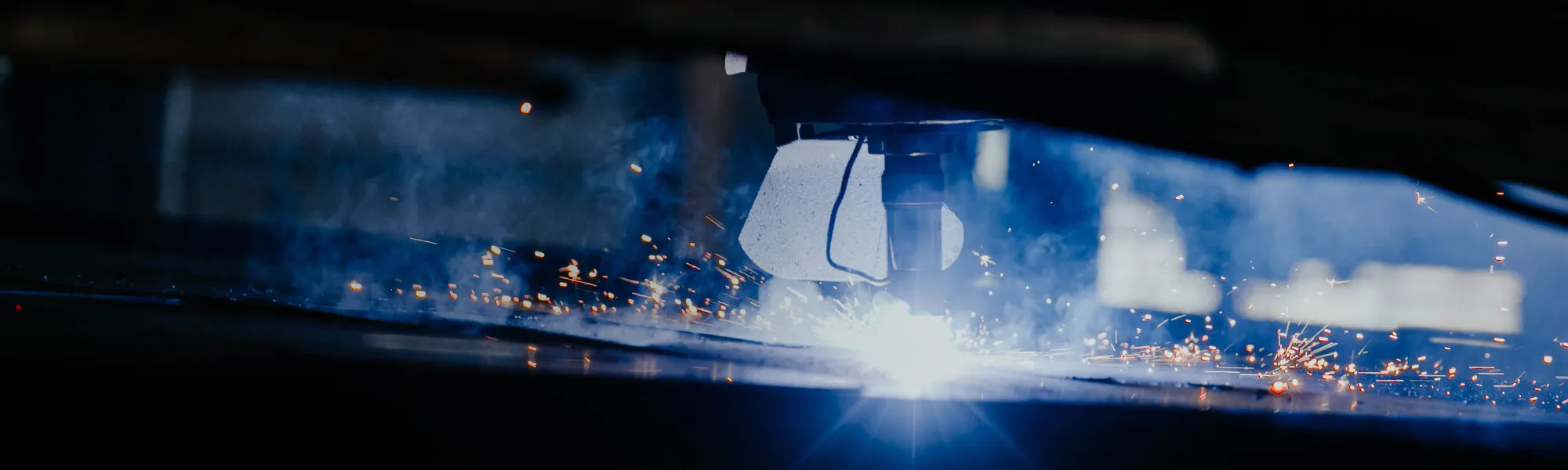

Precision Welding

Our welders are highly experienced in gas-tungsten arc welding (GTAW, formerly known as TIG or Heli-Arc) since we primarily fabricate products from stainless steel and alloys. All welding performed by Shaw Stainless is performed in accordance with American Welding Society (AWS) and ASME (American Society of Mechanical Engineers) welding requirements.

Finishing

Shaw Stainless’ fabricators can provide a wide range of surface finishes on bollards or architectural products. We specifically fabricate to meet the customer’s desired finishes or needs and incorporated into your design requirements. We can provide a number of standard surface finishes and weld finishes; from glass bead, brush finish or electro polished finishes to meet your specific requirements. Our Engineering Department can assist in your surface finish recommendations for your specific application.

Quality Assurance

Our Quality Assurance program tracks fabrication materials, components, and fasteners. From design specifications, purchasing only from qualified vendors, and ultimately through fabrication to ensure that the correct materials are used. All welds performed at Shaw Stainless are visually inspected by our highly trained inspectors after welding. All of our welding procedures, welder qualifications, and weld inspector qualification welds are maintained by Shaw Stainless.

- Laser Cutting, Plasma & Gas Cutting, Waterjet Cutting

- Computer Aided Manufacturing (CAM)

- Steel Beveling Services

- Large Weldments

- Steel Plate Blasting Services

- Steel Painting & Metal Painting Services

- Precision Pipe Cutting

- Miter Cutting

- Cut and Roll Grooving

- Mechanical Torch Cutting

- Flange Attachment

- Galvanizing Services

- Coating, Wrapping & Lining

- Pickling, Oiling & Degreasing

- Electropolishing & Passivation

- Stainless Steel Polishing

- Metal Forming

- Pipe Threading

- Custom Machining

- Independent Testing