316 Stainless Steel

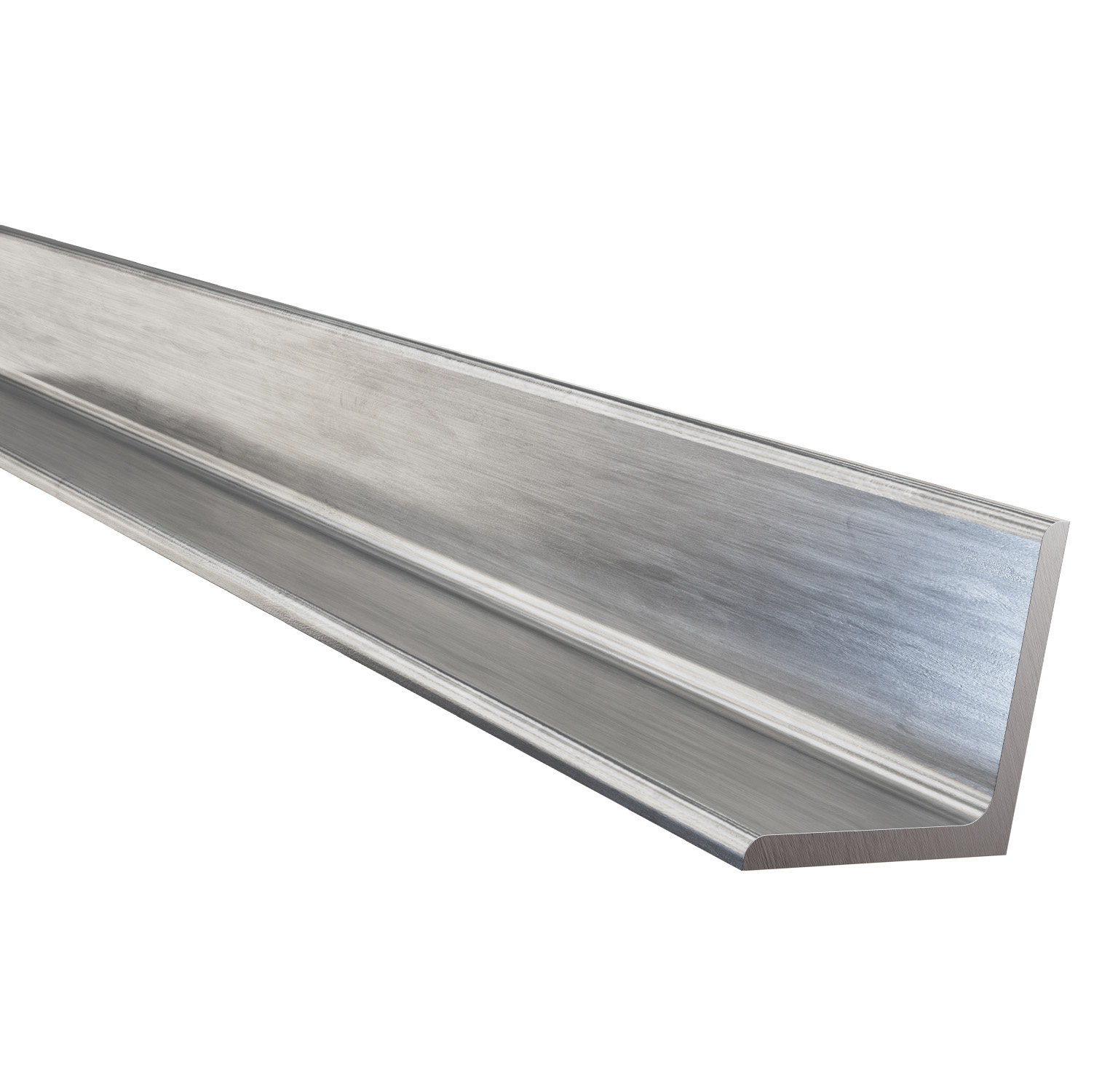

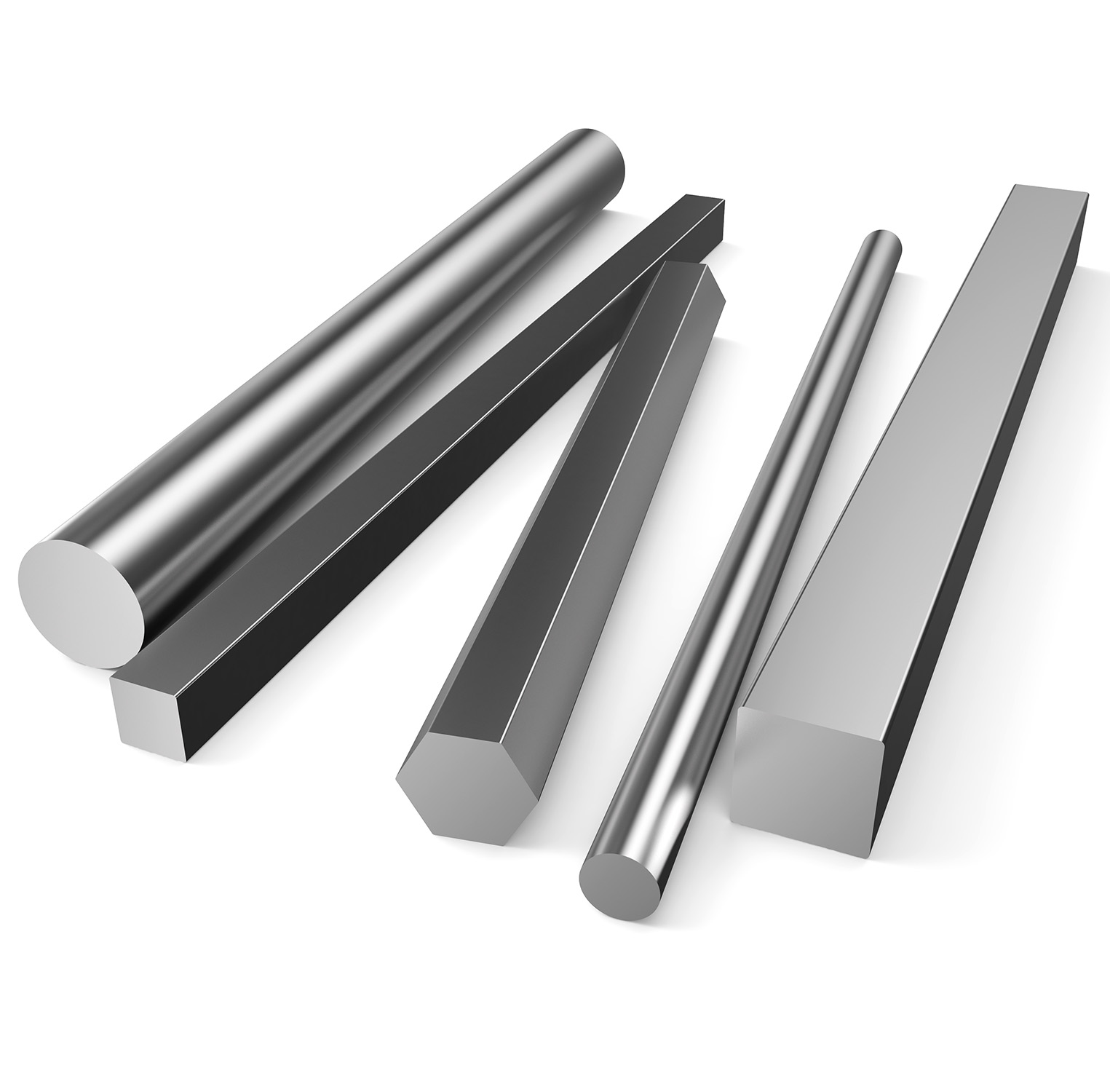

Shaw Stainless & Alloy offers a full-line of 316 Stainless steel products. Select from any of the 316 Stainless steel products below and learn more about the features and benefits, sizes and specifications, and securely purchase online with fast shipping to your location.

Complete our Contact Form to find out how we can accommodate your 316 Stainless Steel needs! To speak to a Shaw Stainless & Alloy Representative call (800) 282-9694 during our business hours.

Contact usAbout 316 Stainless Steel

316 Stainless Steel is commonly used in the food processing industry, chemical, pharmaceutical, marine, textile, and medical industries. One of the main reasons 316 stainless steel is ideal for these industries and their applications is, of course, its corrosion-resistant properties. 316 stainless steel is the second-most used stainless steel grade, behind 304 stainless steel.

Stainless steel is an alloy containing a minimum of 10% chromium. When chromium is added to stainless steel, it produces a thin layer of metal oxide over the surface of the metal, protecting it against corrosive materials.

The addition of molybdenum in 316 stainless steel increases the corrosion resistance as opposed to other stainless steel grades. By keeping the carbon at .03% max, it minimizes carbide precipitation during the welding process. Decreasing sulfur in the 316 stainless steel enhances its ability for electro-polishing. 316 stainless steel is also known as a marine grade due to the increased resistance to chloride corrosion in comparison to 304 stainless steel.

316 stainless steel is in the austenitic group of stainless steel. Austenitic stainless steels are non-magnetic and have very desirable characteristics such as low-temperature strength and toughness, high-temperature strength and stability, good formability, and weldability. 304 stainless steel is also austenitic stainless steel.

316 stainless steel It is the largest group of stainless steel, comprising around two-thirds of all stainless steel production.