Product Info

Seamless nipples are threaded at both ends for various applications. Seamless steel nipples are available in black steel with diameters ranging from 1/8" up to 4" in lengths from close to 72". View an

overview of our product offerings.

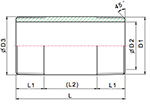

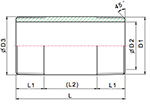

Dimensions

We stock a large inventory of high-quality

seamless nipples to meet your piping needs and specifications. Please review our

product dimensions to confirm your specifications.

Pipe Sizes & Weights

There are many steel seamless nipple sizes to choose. This

pipe chart can assist in your selection and guide you to available, schedule 40 and schedule 80 welded nipple products available at Shaw Stainless.

Standard Specifications

Seamless nipples should comply with ASTM A-53, ASTM A-733 and AHSI B1.20.1. View the

standard specifications chart.

Stainless Steel Grades

Learn about our stainless steel inventory, the functionality and application of various

grades of stainless steel.

Reference Catalog

We designed the Shaw Stainless & Alloy Piping

Reference Catalog as a resource for our clients to identify pipe products and services we offer. This catalog will identify steel nipple products, tube, pipe fittings and other pipe accessories. Specification charts and general dimensional illustrations will help you identify available galvanized nipple products in our inventory.

Theoretical Bursting Pressures

Learn about

theoretical bursting pressures for various stainless steel pipe.

Additional Info

Pipe Cutting and Threading Procedure:

After pipe is cut to a tolerance of 1/16" of the actual length, a visual inspection of seams, welds, and the galvanizing is performed.

Pipe is then threaded, if needed, to American Standard Tapered Pipe Thread standards with a 3/4" taper per foot. Quality pipe is always inspected for the roundness of threads and other visual imperfections as it is removed from the threading machine. Necessary corrections are made at this time to maintain a quality product.